Pasteurizer & Cheese Making – Make your own cheese!

When pasteurizing milk, it is heated (max 100 degrees) and then cooled down to 4 degrees. A signal sounds when the cycle is complete. Then the ripening/preservation phase starts and the milk is kept at a constant temperature of 4 degrees. The agitator can be used continuously or in intervals. In cheese production, the milk is heated to 33 degrees and then starter culture and rennet are added. Once the milk has coagulated, the curd is cut with the cheese harp/stirrer and heated to 44 degrees, separating the whey. When the curd is dry, it is placed in cheese molds and left to press.

About PLEVNIK PH300EZZ 300 liters

- A pasteurizer that is easy to use and guarantees the utmost hygiene. Heating and cooling are thermally transmitted directly through the walls of the tank, which is very economical and saves energy. The machine has two main functions: pasteurization and cold storage.

- Floor model – 2 units.

- The machine can make cheese, pasteurized milk, yogurt and ricotta.

- Easy to use!

- You can set and change temperatures and then save all settings.

- Programs in the computer:

-Up to 10 programs. For mixing, whisking, pasteurizing, washing and chilling the product. -

Equipped with:

– Manual butterfly valve

– Control panel with touch screen

– Agitator, speed 23rpm

– 2-piece lid with flap

– Separate heating/cooling unit with electric heaters and heat pump

The parts are made of food grade material.

Optional extras

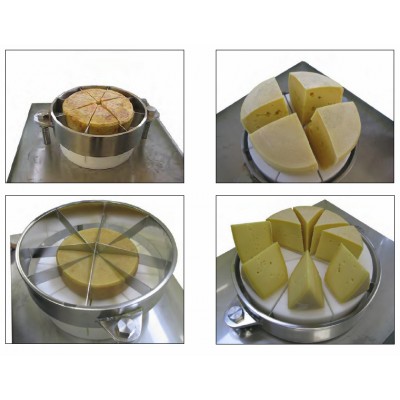

– Agitator for cheese/Ostharpa

– Accessories for cheese making

– Yogurt agitator

– Agitator with scraper blade

– High gloss polishing

– Larger models also available

– Lifting device

– Water cooling